We will provide an in-depth analysis of the drive mechanism and transmission system characteristics of CNC lathe machining for you.

Starting with the transmission pairs – the mechanical transmission pairs of conventional machine tools generally include the following types:

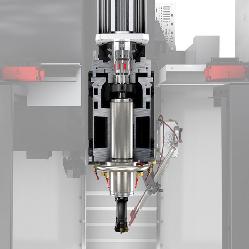

Belt Drive in a Five-Axis Machining Center: It relies on frictional force for transmission, except for synchronous toothed belts. It has a simple structure, is easy to manufacture, and is low in cost. It may slip under load, which can serve as an overload protection function. The disadvantage of belt drive is that it has slippage and cannot be used in applications where precise transmission ratios are required. Application example: Main motor driving the machine tool spindle.

Rack and Pinion Drive in a Five-Axis Simultaneous Machining Center: The gear rotates, and the rack moves in a corresponding straight line. Application example: Heavy-duty gantry tool axis drive.

Gear Drive: It has a simple and compact structure, can transmit large torques, and can adapt to varying speed ratios and loads. It is the most widely used. Its disadvantage is that the angular velocity cannot be too high. Gear drive is currently the most commonly used transmission method in machine tools. Application example: High-torque spindle bearing transmission mechanism.

Worm and Worm Gear Drive: The worm is the driving part, transmitting its rotation to the worm gear. This type of transmission can only be used for the worm to drive the worm gear; the reverse is not possible. Application example: Rotating mechanism of the operating table of a vertical machining center.

Screw Thread Drive: Screw drive uses the engagement of a screw and nut to transmit driving force and motion in mechanical transmission. It is mainly used to convert rotational motion into linear motion and torque into thrust. Application example: Ball screw drive, and threading on a conventional lathe.

24-Hour Hour Hotline

Contact person | Wang Lingli (Manager) |

Contact information. | 13968328508 |

wll@nbchengdi.com | |

Add | Room 1202, Huia International, No. 1107 Tian Tong North Road, Yinzhou District, Ningbo City |

Landline number | 0574-87267001 |