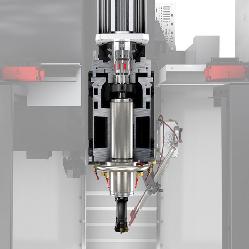

The scope of processing for a five-axis machining center is very broad, capable of machining parts that cannot be machined or are difficult to machine with basic three-axis machines. Moreover, the industries involved with five-axis machining centers are quite diverse, primarily including aviation, aerospace, defense, scientific research, high-precision medical equipment, and high-precision machinery manufacturing, which are industries highly valued by our country. It is evident that five-axis machining centers have significant influence in these highly valued industries. A five-axis machining center can machine various complex curved or irregular parts, such as turbine engine blades, aircraft engine propellers, marine propellers, and other such complex curved and irregular parts. Customers who purchase five-axis machining centers typically need to machine parts with very complex shapes and do not use them for machining simple planar or simple curved parts. Using a five-axis machining center to machine simple planar parts would be a waste of its capabilities. Compared with conventional machining centers, five-axis machining centers have the following distinct characteristics:

High Machining Precision

A five-axis machining center can perform detailed inspections of material specifications through five-axis precise positioning machining, so the precision of a five-axis vertical machining center is higher than that of a conventional machining center.

Good Manufacturing Conditions

The level of CNC machine tool automation is high, greatly reducing the workload of operators and providing a better working environment.

24-Hour Hour Hotline

Contact person | Wang Lingli (Manager) |

Contact information. | 13968328508 |

wll@nbchengdi.com | |

Add | Room 1202, Huia International, No. 1107 Tian Tong North Road, Yinzhou District, Ningbo City |

Landline number | 0574-87267001 |